PAPER EXPO 2025 Shanghai International Paper Exhibition grandly opened on August 13 at the Shanghai World Expo Exhibition and Convention Center, aiming to build a "one-stop" paper industry exchange and procurement platform for papermaking companies.

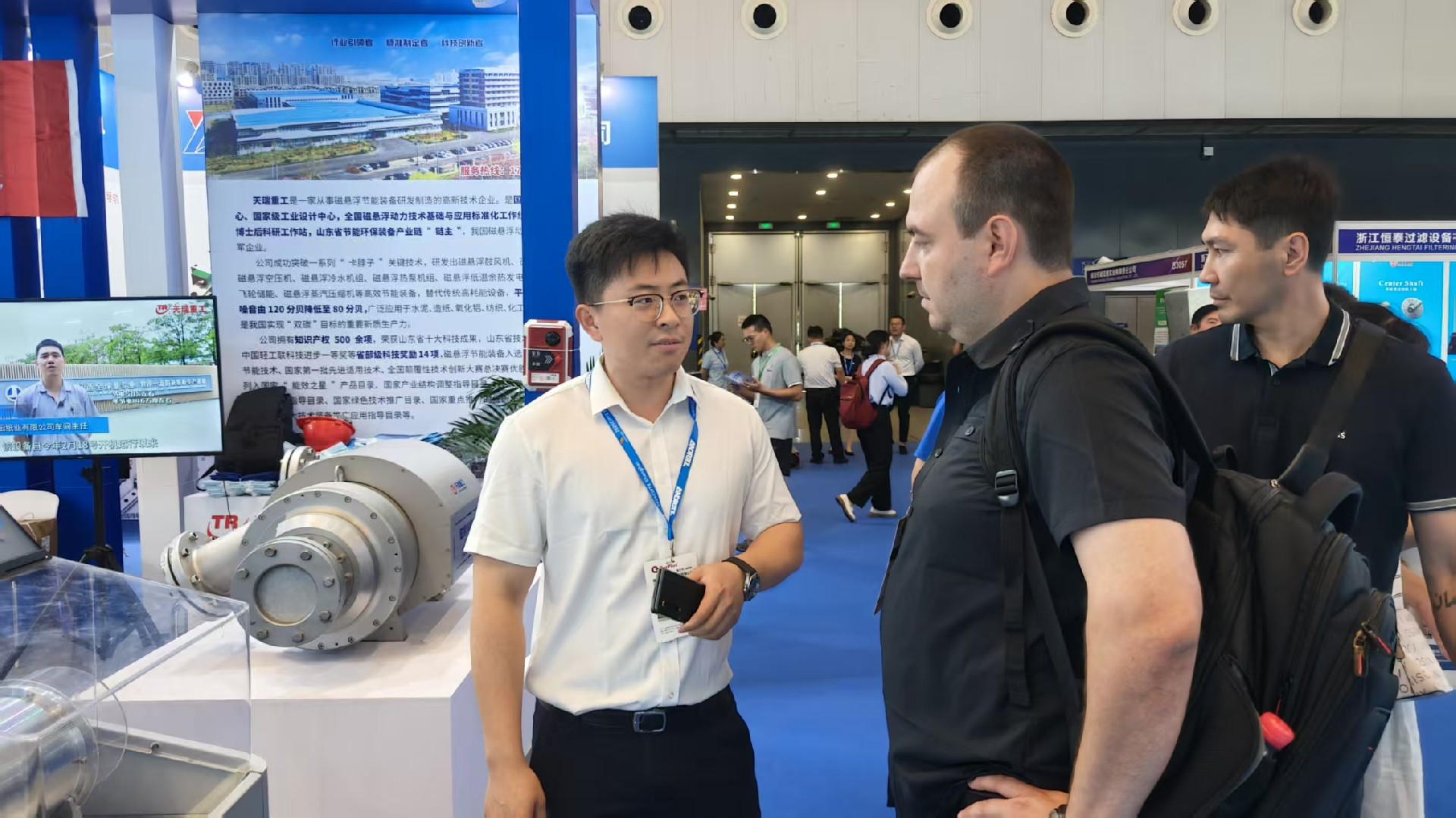

Among the many exhibitors, Tianrui Heavy Industry attracted much attention. The world's first high-speed and wide-width (7360mm) paper machine line using maglev vacuum pumps further highlighted the stability and reliability of Tianrui Heavy Industry's products in the paper industry.

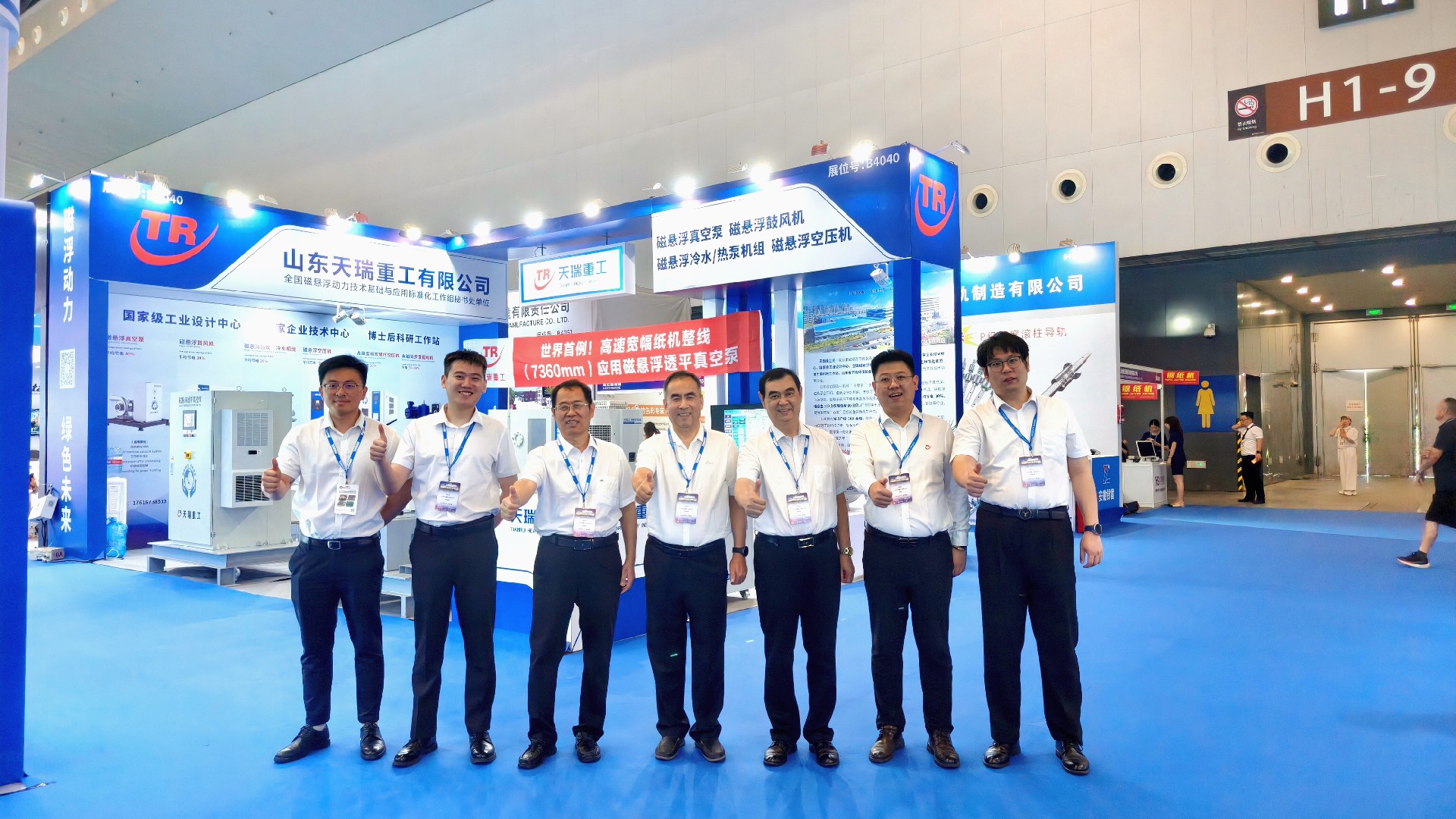

Tianrui Heavy Industry has always contributed new-quality productivity to the green development of the paper industry. During the exhibition, leaders from the organizers, including the China Pulp and Paper Research Institute, the China Paper Association, the China Paper Society, and provincial papermaking associations, visited the Tianrui Heavy Industry booth and took photos.

Tianrui Heavy Industry is deeply involved in the entire production chain of the paper industry, providing customized, one-stop maglev solutions to address production pain points and difficulties. Currently, Tianrui Heavy Industry has provided professional services to hundreds of papermaking companies and has established in-depth cooperation with many leading papermaking companies, including APP Paper, Xianhe Paper, Sun Paper, Huatai Paper, Shanying International, and Yatai Sun Paper.

Maglev Vacuum Pump - Efficient Vacuum Dehydration

In January 2023, a large paper group installed nine of our maglev turbine vacuum pumps. Five of these pumps replaced nine water ring vacuum pumps on production line No. 3, reducing power consumption per ton of paper from 155 kWh to 87.3 kWh. This represents a 43.67% savings of 67.7 kWh per ton of paper, saving 6.728 million kWh annually.

Production line No. 1 uses 4 maglev turbine vacuum pumps to replace 4 water ring vacuum pumps. It has been running stably since it was started up in November 2023. The electricity consumption per ton of paper was 156.66 kWh before the transformation, and the electricity consumption per ton of paper was 85.71 kWh after the transformation. One ton of paper saves 70.95 kWh of electricity, and the electricity saving rate is 45.3%, saving 5.848 million kWh a year.

In this project, the application of maglev vacuum pumps can save the company 12.576 million kWh of electricity each year and save more than 8 million yuan in electricity bills.

Maglev Blower - Efficient Sewage Treatment

In April 2016, a paper industry group implemented an energy-saving retrofit for its wastewater treatment system, replacing its existing Roots blowers with five maglev blowers. Over the past eight years, these blowers have operated stably and achieved significant energy savings, exceeding 37%. This translates to an average annual electricity savings of over 1.5 million kWh and over 1 million yuan in electricity bills. The noise level has also been reduced from 130 decibels to below 80 decibels, significantly improving the working environment.

Maglev Chiller - Efficient Process Temperature Control

In September 2023, a paper mill installed one 400 refrigeration ton (RT) Tianrui Heavy Industry maglev chiller unit to replace its original screw chiller for process cooling. This achieved an electricity saving rate of 45.5%, saving 465,600 kWh annually, while fully meeting the production requirements of the workshop. Subsequently, in January 2024, the company installed another 500 RT maglev chiller unit to replace its original screw chiller. This achieved an electricity saving rate of 45.2%, saving 318,400 kWh annually.

In the future, Tianrui Heavy Industry will continue to deepen its roots in the paper industry, contribute more to the paper industry's energy efficiency standards and green transformation, and make great strides in promoting the industry's green development!