People in the industry know that the blowers used in cement plants are generally used for pneumatic conveying and flue gas desulfurization. At present, the blowers widely used in domestic cement plants are generally roots blowers. Although the principle and structure of Roots blower are simple, the safe operation, service life and power consumption of the blower have always been a major problem in the water turbine industry.

The roots blower must have certain preconditions when it is used. It must be started without load and cannot be stopped suddenly under full load operation. Otherwise, the blower will be damaged and its service life will be shortened. At the same time, during the use of Roots blower, special personnel must be arranged for regular patrol inspection on a shift basis, and the blower needs to be overhauled once a year to ensure the safety and rated air supply of the blower.

In addition, the data in recent years show that the rising electricity price has further increased the proportion of electricity consumption in the cost of cement plants. As a large power consumer, energy saving and power reduction are imminent for all cement plants. The power consumption of Roots blower is huge in the process of use, and the cost of electricity used by the cement plant rises again and again due to the hundreds of thousands of millions of electricity charges. Therefore, it is urgent to upgrade the blower.

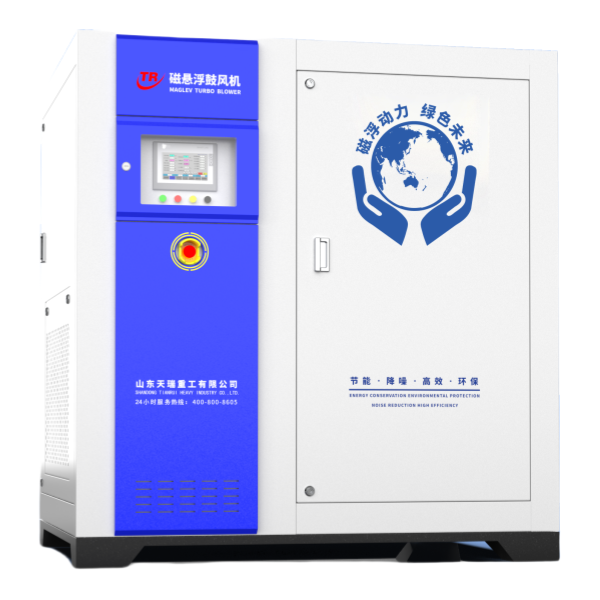

Compared with the use of Roots blower, which requires regular patrol inspection, large power consumption and large noise, the maglev blower developed and produced by Tianrui heavy industry has obvious advantages in the above aspects.